Unit to Studio Conversion

Creating a sound stage

Our objective was to design and build a professional, industry-standard production space from a neglected warehouse… Faced with a leaky roof, cracked concrete floor, industrial heating system, large heavy safe and a raised loading bay with rattling metal shutter doors, presented some unique challenges as we set out to design, build and deliver an acoustically treated sound stage for our clients film and still photography studio.

As always we embrace a challenge and set out to repurpose this old dilapidated unit to create a fit for purpose production studio. Initial prep involved removing old metal ventilation system, the ancient boiler, vents in the roof, fraying electrical cables and a large and very heavy old (empty) safe.

The exterior roof was overlaid with 100mm of sound insulation encapsulated with steel roof panels to stop leaks, retain temperature and improve noise pollution. The new steel roof was topped with Silent Roof material to prevent noise pollution caused by rain hitting the hard metal surface. The facade was partially rendered and painted, parking spaces created by removing bollards, minor general repairs and to cap it all – a brand new light up LED studio sign.

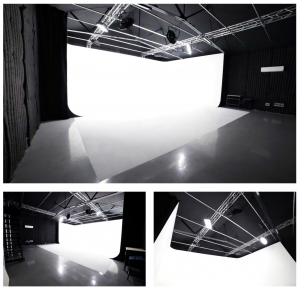

The interior space benefitted from a new electric system, 3 phase and 13 amp, Two 10kw HVAC units, an acoustically treated suspended ceiling fitted inline with the roof pitch to retain the space below, the entire ceiling, metal rafters and beams was painted black. We then built bespoke specification sound walls with over 72dB reduction all round with large bespoke loading bay doors, MOE doors all with matching black door furniture. The doors received a rubber edge and backing strips with seals all round to help prevent sound loss, while the concrete floor was ground down to a smooth level surface, cracks filled and then painted with a light grey epoxy resin.

The infinity cove at 5.2m deep x 10.4m wide x 4.2m high was unique in build, the client requested a bespoke semi-modular structure that blends into the floor while incorporating an element of ‘portability’ giving the option to dismantle in future and move to another location with minimal repairs.

Once all the walls were completed, the addition of ABS (acoustic barrier system) – a class ‘A’ sound absorption product – installed on three walls in front of the cove removed reverb, echo and has helped to achieve impressive sound reduction levels within the new studio space.

In addition to the studio space we refurbished a green room, installed a new kitchen, bathroom and refurbished an old storage room into a rather smart MUA station.

As usual we went above and beyond to complete an acoustically treated production space, under budget leaving funds available to add a very comfortable green room, excellent facilities and dedicated parking bays. The studio is very popular, extremely busy and our client is very happy!

For further details please write to email@tvstudiogroup.com