The images below give an example of a standard industrial unit that was converted into a fit-for-purpose production space, with complete internal fit outs, acoustic sound slab walls, sound partition walls and quilted fabric for improved acoustic performance. You can view more information on this project in case studies.

Acoustic Performance

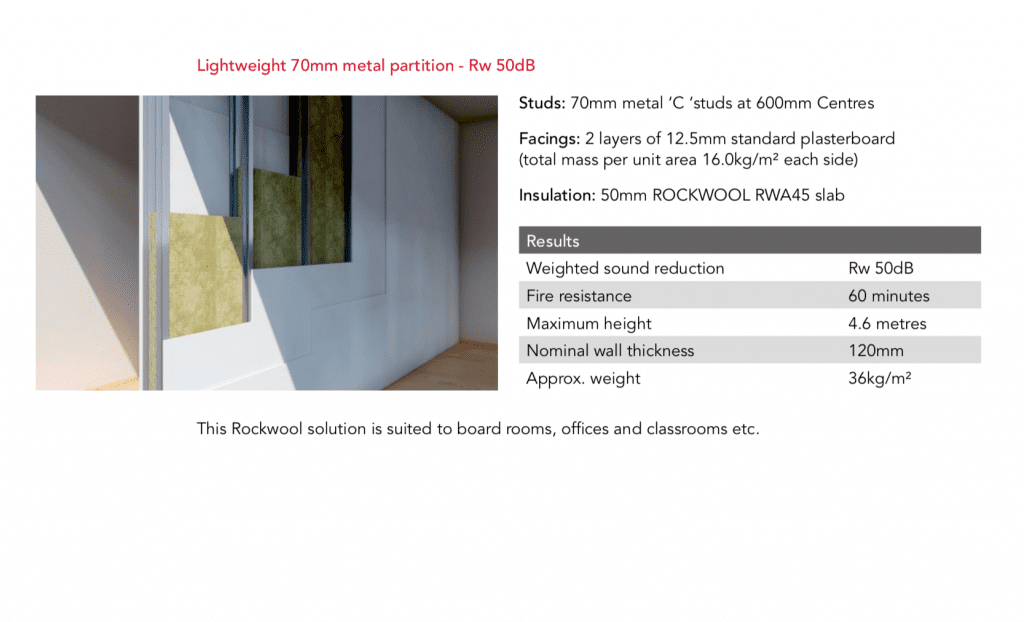

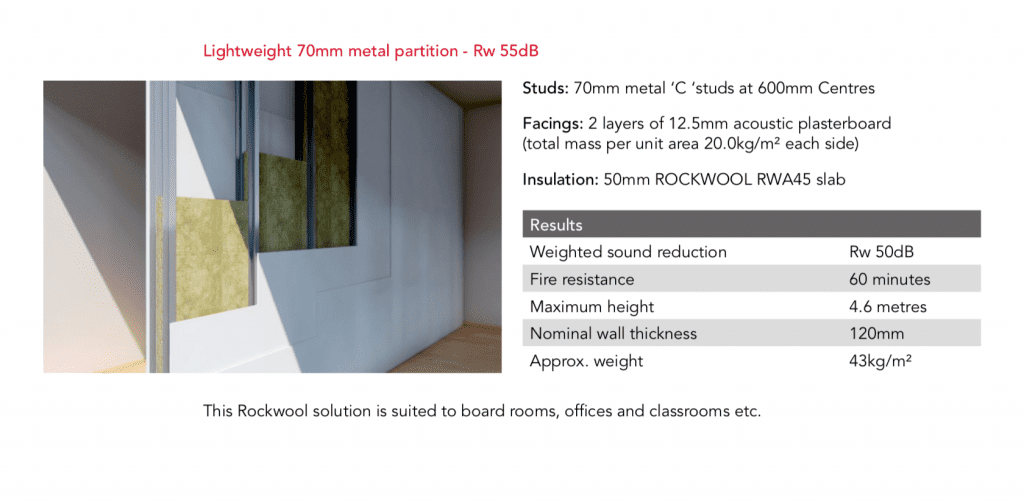

A standard sound wall can offer good performance when it comes to sound penetrating from one studio to another, however our own mix of acoustic rubber in addition to sound boards and rockwool sound slab can achieve above and beyond 50dB reduction. The structure of the fibres in Rockwool RW slabs make them ideal for use as a sound absorber. Rockwool stone wool products work in two distinct ways to reduce noise, either by impeding the transmission of sound through an element of the structure or by absorption of sound at the surface. ROCKWOOL products also help to improve the fire rating of a partition by limiting the transfer of heat across the cavity.

Stats & charts

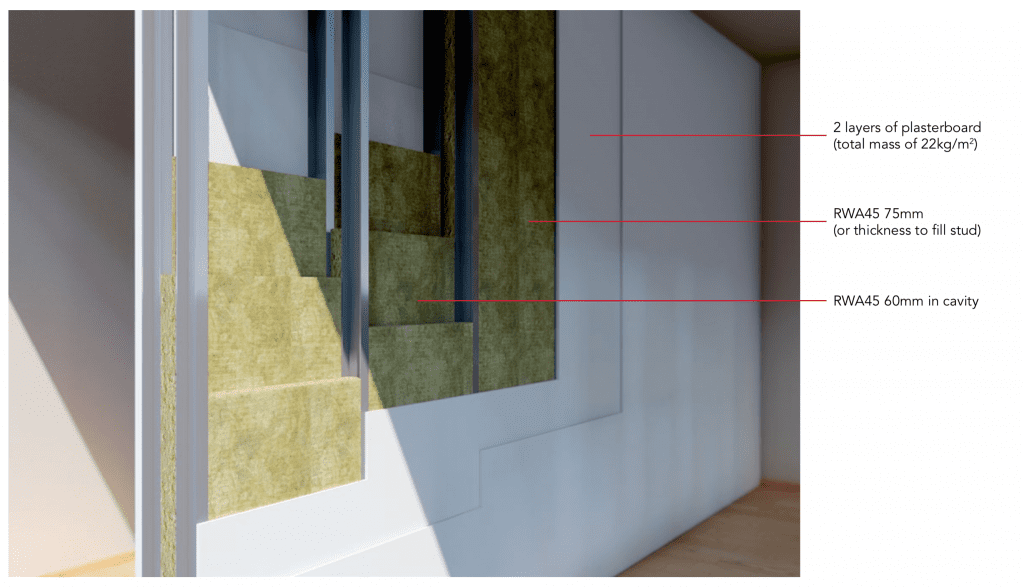

Typical Twin light steel frame construction with two separate steel frame walls constructed with a minimum 60mm RWA45 slabs, slotted into the cavity between the two steel frames and butt jointed. (Actual thickness of insulation will be determined by the as built cavity width between each frame).

Fully fill the depth of the frame on both sides with 75mm RWA45 slabs, (or thickness to suit stud depth) with no gaps between the insulation slabs. As a wall lining we recommend two layers of 12mm sound board (or 15mm) each side of the party wall, with all joints staggered, to provide a total nominal mass per unit area of 22kg/m2 both sides. A minimum width of 200mm is required between the inner faces of plasterboard lining and finished with all joints sealed in the outer leaf with joint tape or caulk sealant.

CLICK HERE for a handy absorption coefficients chart to assist with frequency Hz in all material types.